Recent Projects

Below you will find a selection of recent work. If you have a project you feel we may be a good fit for, please get in touch.

De-chlorination tablet feeder funnel boxes

A client asked us to design & manufacture rectangular de-chlorination tablet feeder and funnel boxes. They needed to be manufactured using stainless steel and have removable lids. All components used needed to be environmentally friendly and cause no harm to wildlife.

These will be used within existing treatment systems where waste water chlorination is being added or to replace complicated chlorination systems to ensure the chlorinated water is diluted and made safe before it re enters the water course thus protecting the environment. Also killing off any harmful bacteria.

Suitable for installations in fisheries, small industrial plants as well as various other platforms.

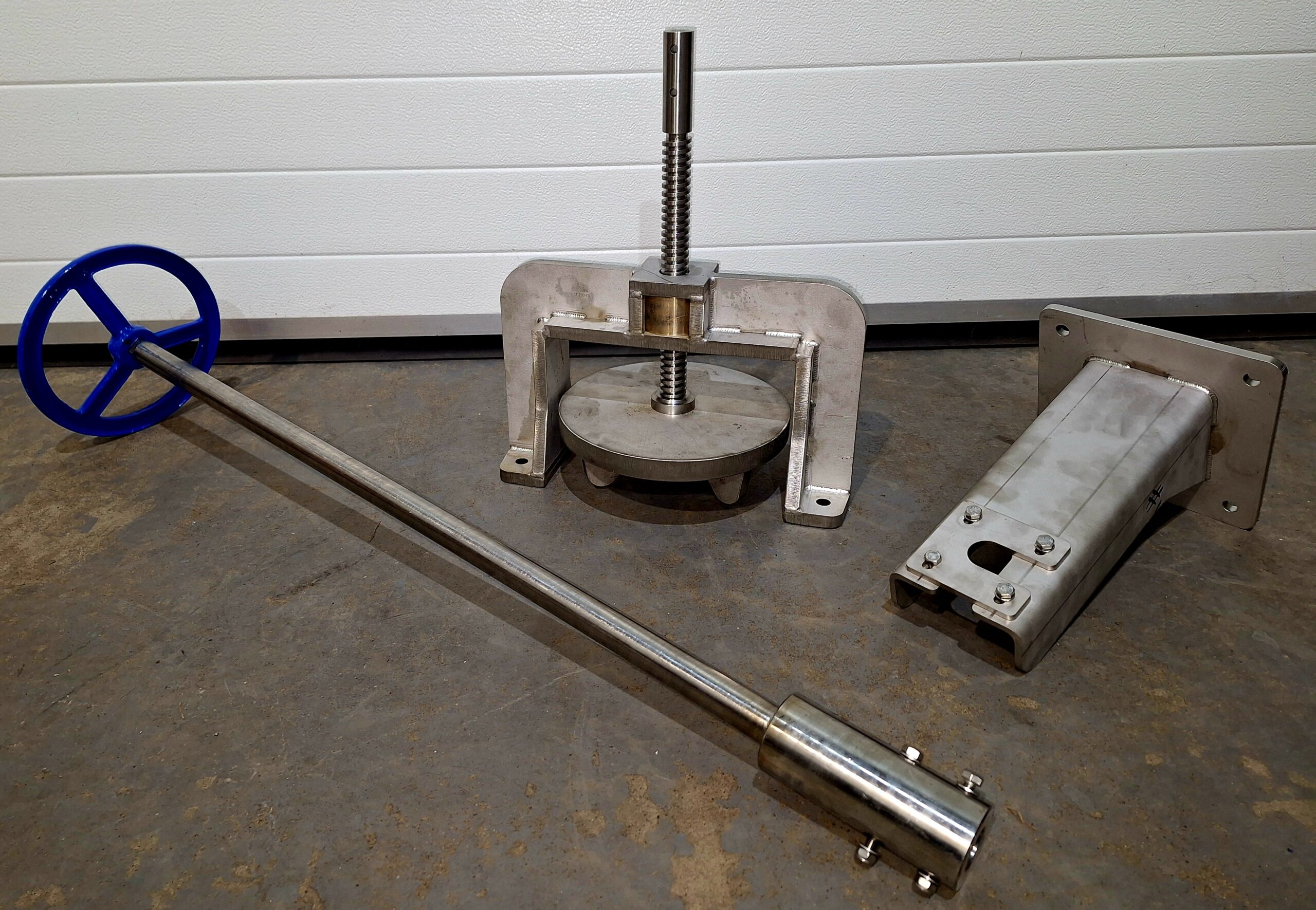

Bespoke Machined Valve with Operating Handwheel Assembly

As well as our core fabrication skills offering, SDR can also provide high quality bespoke machined items tailored to individual customer requirements.

We were recently engaged by a client to manufacture three replica plug valves. We were supplied with a rusted, worn pattern part which we redesigned so that it could be fabricated in stainless steel. Our skilled machining team then turned the necessary metric square thread lead screws from stainless steel bar and matching bronze nuts. The nut part was then milled square to fit neatly into the valve body fabrication.

As per the photos we also produced valve operation/extension handwheel assemblies and the associated supporting brackets to fit seamlessly back into our customers site installation in place of the original valves.

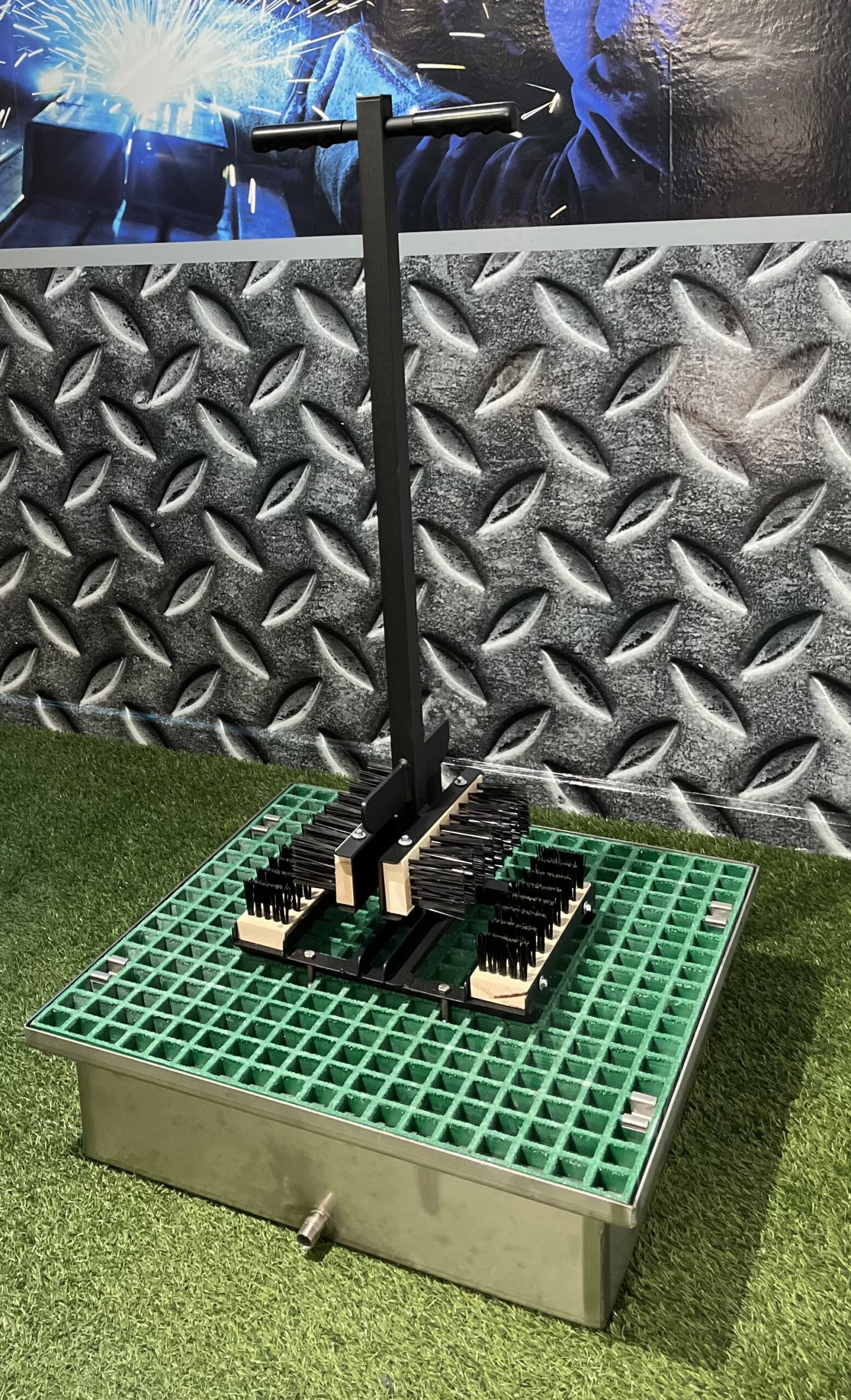

Anglers' Dip Tanks

Anglers’ dip tanks will be installed at a local fishing lake.

Dip tanks will be used by the anglers to clean their fishing tackle. Anglers will be able to clean their equipment to avoid contamination and to help prevent the spread of fish diseases and parasites.

The dip tanks have been manufactured using stainless steel and eco friendly composite cladding. The tanks shown in the photos were fabricated to customer requirements.

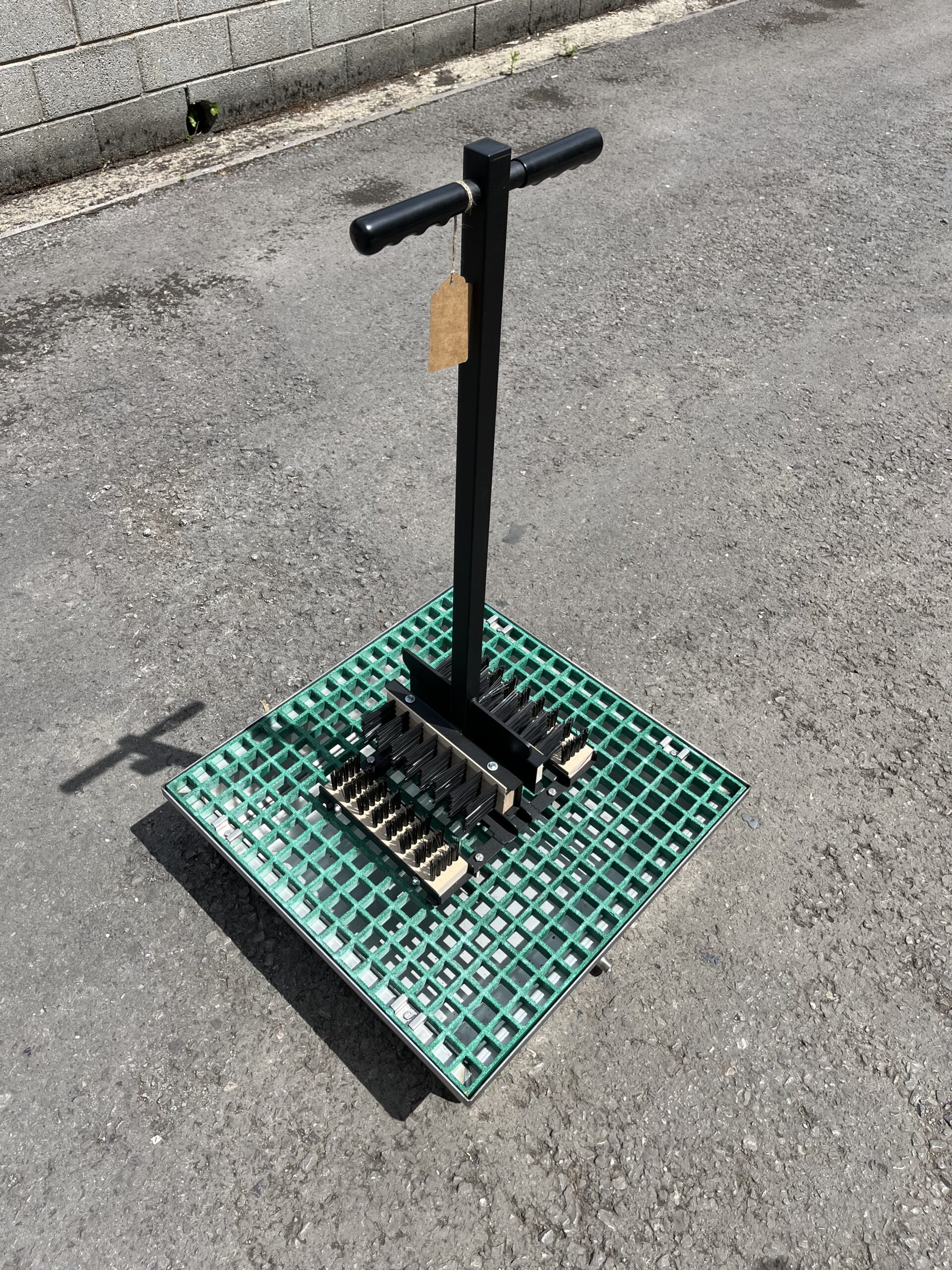

Boot Scraper

Recently completed boot scraper for Utilities company which was manufactured from stainless steel. They will be used within the local region to help control the spread of INNS and encourage the protection of biodiversity within the environment.

This was manufactured to customer specification and allows visitors to sites to clean footwear and discourage the spread of Invasive Non Native Species (INNS) before returning to their vehicles and clean areas.

INNS can be devastating to biodiversity and can have a detrimental impact to the economy and ecology.

Mild Steel Tank

Recently Fabricated Media Filter Tank with internal bracing.

Tank was fabricated from Mild Steel and had to include internal bracing for structural integrity, a 100mm drain down point and 2 x 200mm flanges

It was then coated with Grey Primer before receiving a coat of green.

Tank measures 3m x 3m x 2m and when full will weigh approximately 18 tonnes

Acoustic Generator Enclosure

The new generator housing was manufactured in our workshop for a utility company. Measurements were taken on-site and then installed by our team with minimal disruption. Due to the proximity of residential buildings, the noise emission of this enclosure had to be whisper-quiet.

We are able to manufacture a whole range of enclosures to suit any environment.

P&O Cruise Ships - Galley Refurbishment

New galley was fabricated off site ready for install .

Removal of old galley and installation works were carried out during an over night shut down of kitchen to allow for minimal disruption.

P&O Cruise Ships - New Railings and Gate

Railings and gates were fabricated and a paint finish applied off site following customer requirements this allowed for minimal disruption during removal of old railings and gate and the installation of new.

Bulkhead Screen System

This bulkhead screen system is installed directly over the flow path of an existing storm drain to collect all debris and prevent them from entering the water course, helping to protect wildlife and preserve the environment. Solids are retained in a smooth, easily interchangeable collection bag when full. The modular design can be adapted to most existing applications.

Access Steelwork

We were tasked with finding a robust solution to overcome a difficult access and egress situation. We carried out a site visit to take precise measurements before manufacturing an access platform and ladders with a galvanised finish.

At SDR, we pride ourselves on our ability to deliver customised solutions to meet the unique needs of our clients.

We have the knowledge and experience to design and fabricate access platforms and ladders to the highest standards, ensuring that they are durable and able to withstand the demands of the environment.

PST Tank Capping

We recently installed a custom tank cover capping fabrication on-site at a water treatment facility. This was a critical step in preventing further deterioration of the concrete structure, which had caused the rotating bridge to become unstable, ultimately leading to premature failure of the asset.

We the expertise and capability to design and fabricate custom tank cover capping solutions that are both functional and durable, ensuring that they provide long-lasting protection for the underlying structure.

Access Walkway

We were commissioned to fabricate an access walkway and platform with hand-railing for an aggregates company. The walkway was to be installed over a man-made lake. We fabricated the components in our workshop, galvanised them, and then transported them to the site for installation by our engineers.

All components of the access walkway and platform were manufactured according to the client’s supplied specifications and drawings while adhering to EN: 1090 standards. This approach ensured that the solution we delivered met the highest quality standards and was both functional and safe.

Bespoke Cover

A bespoke chequer plate cover, fabricated and installed on site. The requirements from the client were to allow for access to existing valving arrangements whilst covering a deep chamber for safety.

Air Compressor Acoustic Enclosures

This project involved the design, fabrication, and installation of custom air compressor acoustic enclosures for a client. The enclosures needed to suppress noise output while ensuring that the equipment inside remained cool, even when operating at high temperatures.

Our team has the knowledge and experience to design and fabricate acoustic enclosures that are both functional and aesthetically pleasing. We use the latest technology and equipment to ensure that our fabrications meet the highest quality standards.

Our commitment to delivering exceptional results is evident in the before and after images of this project.

Reception Main Entrance Walkway

For this project, we fitted non-slip flooring to the ramp to ensure that it was safe for use by disabled individuals. We applied a white paint finish to the hand-railing to provide a clean and professional appearance.

Our commitment to delivering high-quality solutions is evident in our work, and we are proud to have provided a safe and accessible solution for this customer.

Bespoke Metal Fence

Private client requested a bespoke fence . After discussion with customer we were able to fabricate, apply finish and install fence posts and panels.

In total 7 panels were fabricated and fitted.

Bespoke Gate and Two fixed panels

Private client requested bespoke gates with fixed side panels. This was to follow on from the new metal fence panels previously supplied by us.

Tank Pipe Work Repair

After removing the old temporary welded patch on an oil tank, we fitted a new permanent patch that was painted according to the customer’s specifications.

At SDR, we understand the importance of delivering solutions that meet the highest safety and quality standards. To ensure that the patch was safe and secure, we had the job MPI (Magnetic Particle Inspection) tested by an external supplier.

SITE VISITS AND TURNAROUND

We provide site visits to measure, discuss and propose ideas and offer advice on your construction requirements, enabling us to take your product conception to a finished customised product.

Depending on the scale and complexity of the design needed, we can turn around the drawing in 2 – 5 working days.

Once you are satisfied with our design we are able to provide you with a quote including time scales for fabrication and completion.